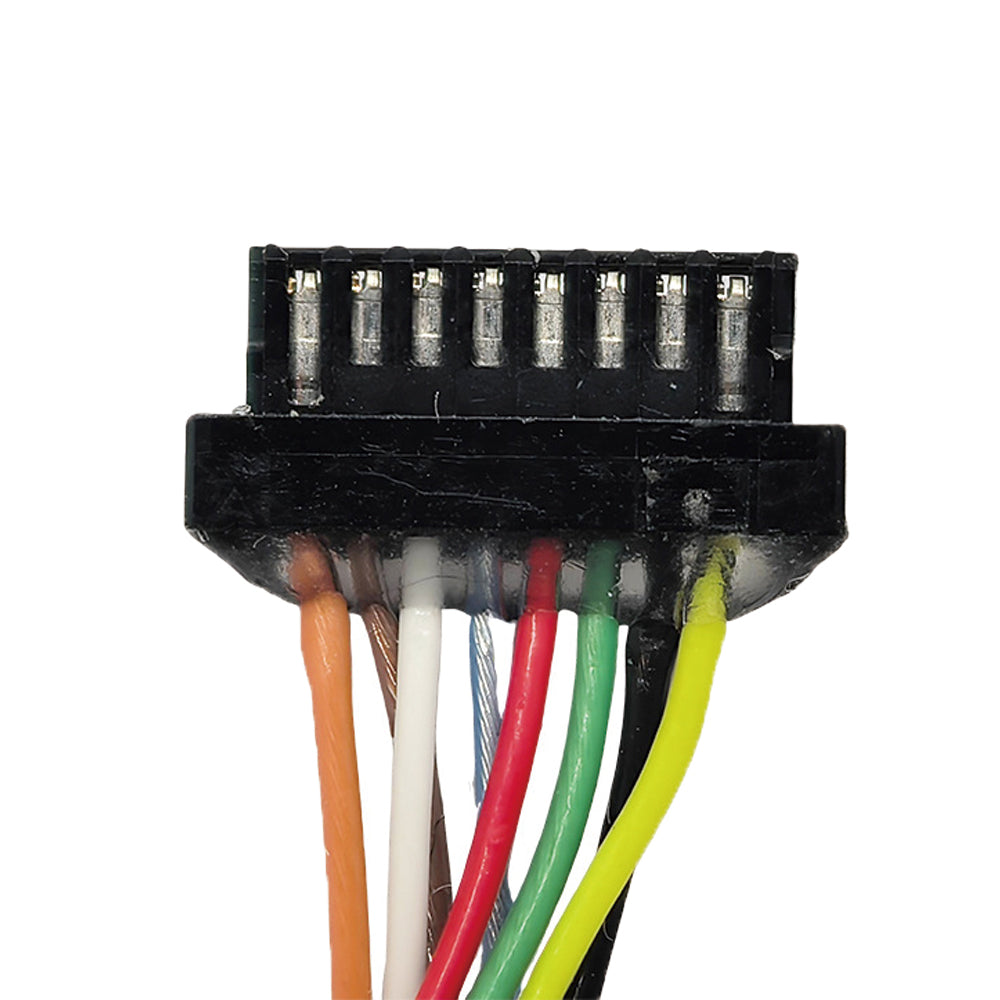

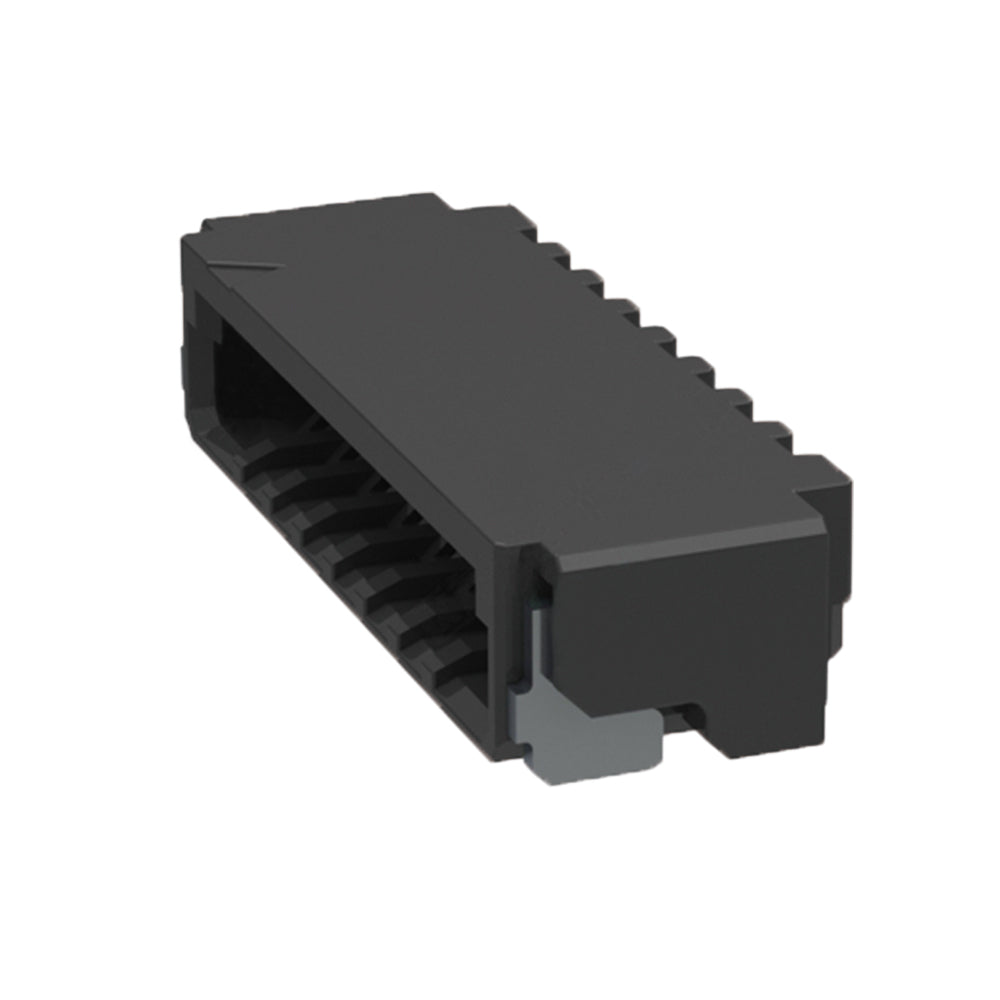

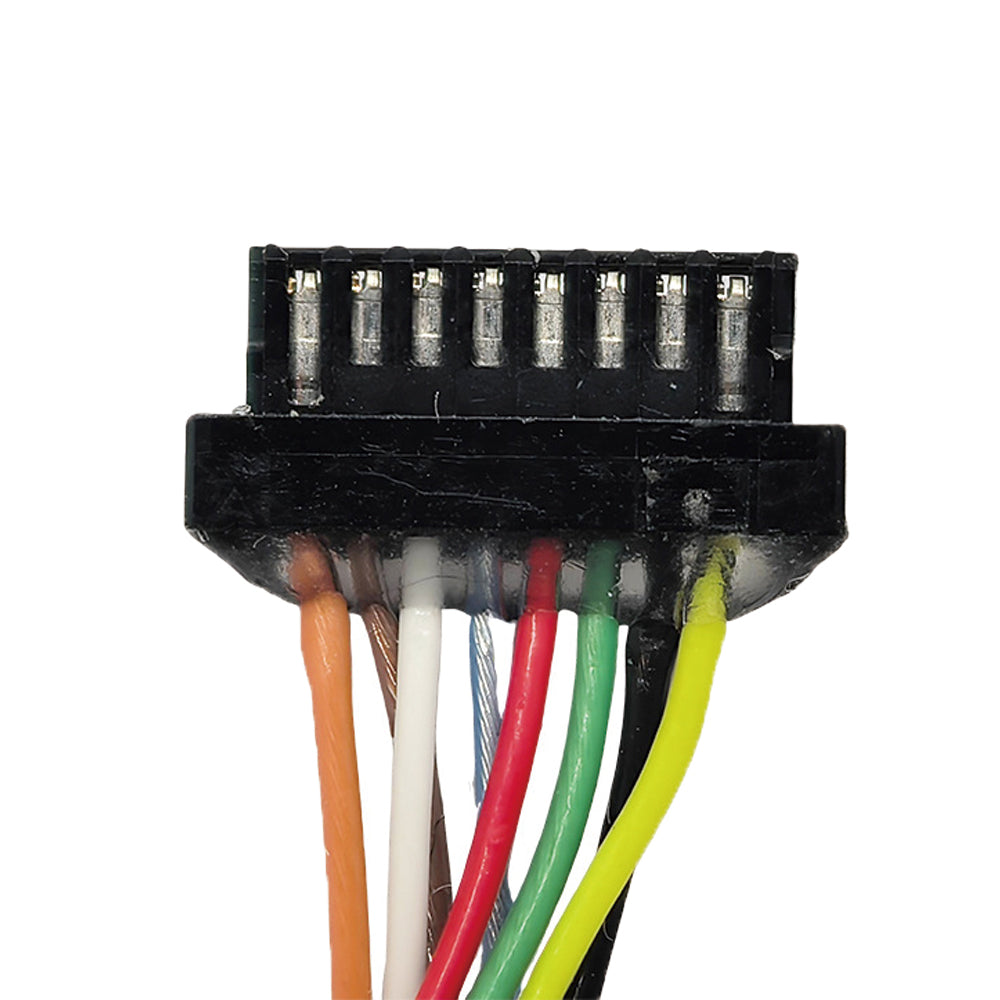

Hirose DF53-6P-0.6H Plug Connector IDC Cable Terminal Wire Harness

Key Product Features

- Precision Pitch Design: 0.6mm ultra-fine pitch ensures space-saving connectivity, ideal for compact electronic devices where board real estate is critical.

- Puncture Connector (IDC Technology): Eliminates the need for soldering, enabling fast, secure, and consistent terminations that reduce assembly time and minimize human error. The insulation-piercing mechanism creates a gas-tight connection for long-term reliability.

- DF53-6P-0.6H Compatibility: Perfectly matched to DF53-6P-0.6H connectors, ensuring seamless mating and optimal electrical performance. Available in 6-position configurations, with customizable pin counts upon request.

- High-Quality Construction: Crafted with premium copper conductors (28AWG/30AWG optional) and durable insulation materials (PVC/XLPE), resistant to abrasion, temperature variations (-20°C to 85°C), and chemical exposure.

- Customizable Length & Termination: Choose from standard lengths (100mm–5000mm) or request a precise cut-to-length solution. Optional terminations include stripped ends, pre-crimped terminals, or custom connector interfaces (JST, Molex, TE compatible).

Pairs well with

In stock! Ships within 1-2 business days.

90-day risk-free trial

2-Year Warranty

Complimentary shipping & returns

Hirose DF53-6P-0.6H Plug Connector IDC Cable Terminal Wire Harness

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Product Category

Terminal wires are essential connecting components widely used in electronics, communications, automotive, and home appliance industries.

Customized Wire Harness

100% Raw Material Inspection → Precision Manufacturing → 3-Stage Quality Testing → Packaging & Delivery

Raw Material Inspection: Verify material specifications, insulation performance and environmental indicators.

Precision Manufacturing: Adopt automatic equipment to reduce manual errors and ensure consistent product dimensions.

3-Stage Quality Testing: Includes initial sample testing, in-process random inspection, and final finished product testing.

Packaging & Delivery: Anti-static packaging for electronic components; customized packaging solutions for bulk orders.

Our Advantages

🔍 Full Certifications

ISO/UL/ROHS/REACH compliant

🛠️ Customization Flexibility

Tailor length, terminal type, color & shielding

⚡ High Reliability

Anti-corrosion, vibration-resistant & stable signal transmission

⏱️ Fast Lead Time

Standard models in stock, custom orders in 7–10 days

FAQs

Please read our FAQs page to find out more.

Can you help to design?

Yes,we are an OEM/ODM company,we have been specializing in wire harness and cable since 2014.

Can you provide samples?

Yes,the sample is avaliable to provide for testing or checking quality before mass production.

If I don't have any drawings,can you still quote my products?

Yes,but we need you to provide information about the length and gauge of the wire,the part number of the connector,etc.

What are the common applications of terminal wires?

Terminal wires have extensive applications across multiple industries:

• Consumer electronics: Used in smartphones, laptops, TVs, and printers for internal component connections.

• Automotive industry: Applied in engine control units, lighting systems, and dashboard circuits.

• Industrial equipment: Utilized in PLCs, sensors, and motor control systems.

• Household appliances: Found in refrigerators, washing machines, and air conditioners.