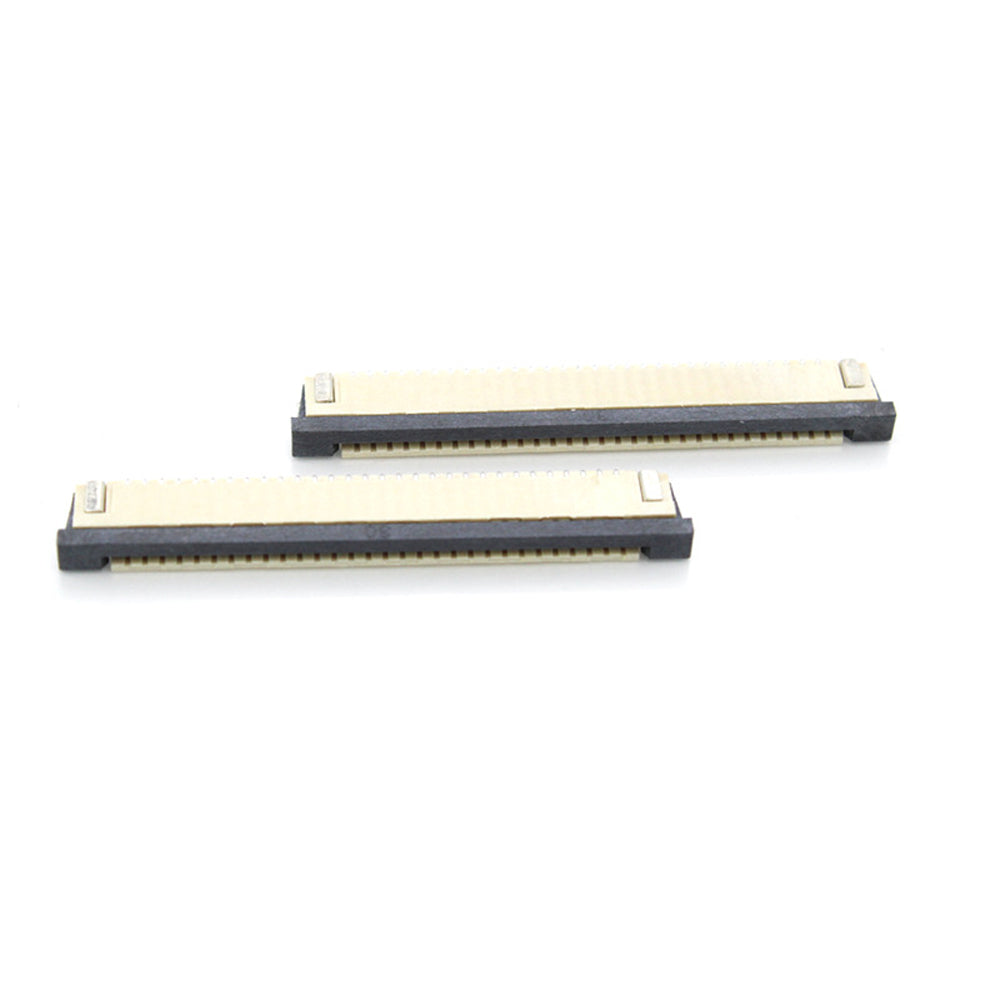

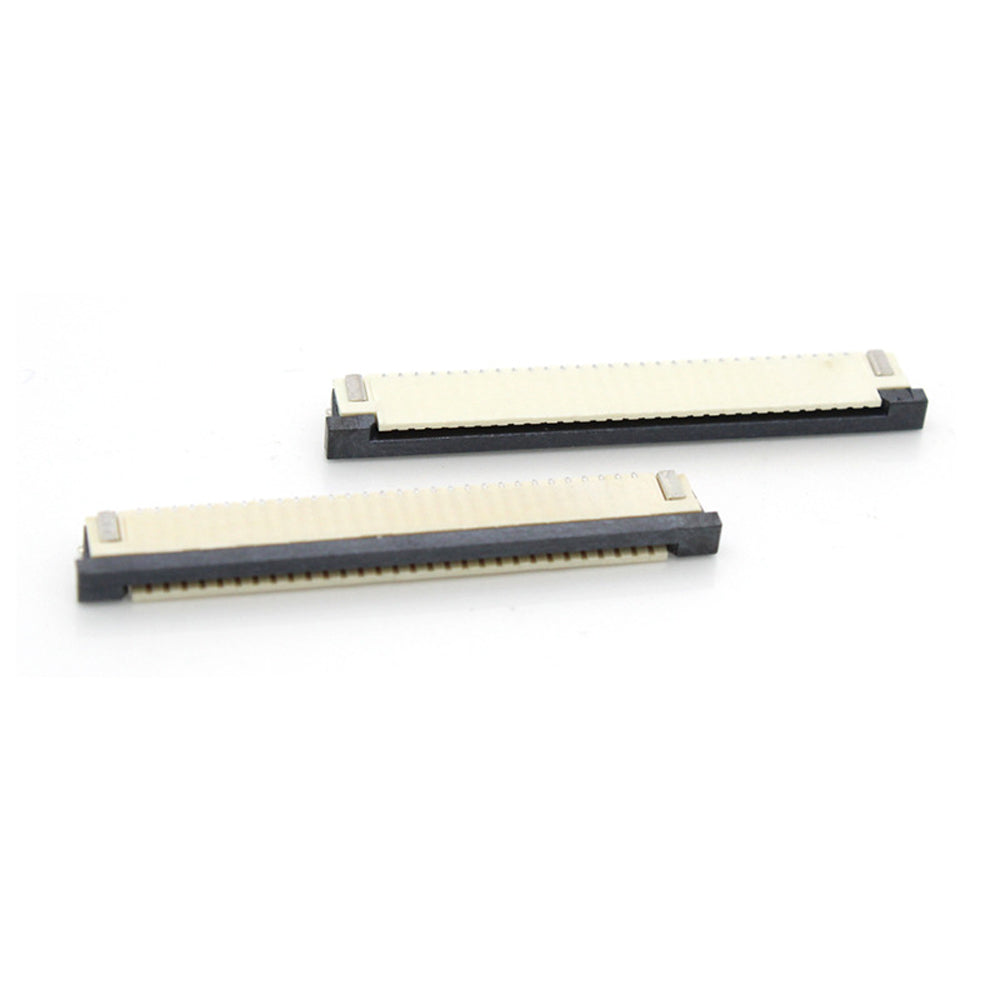

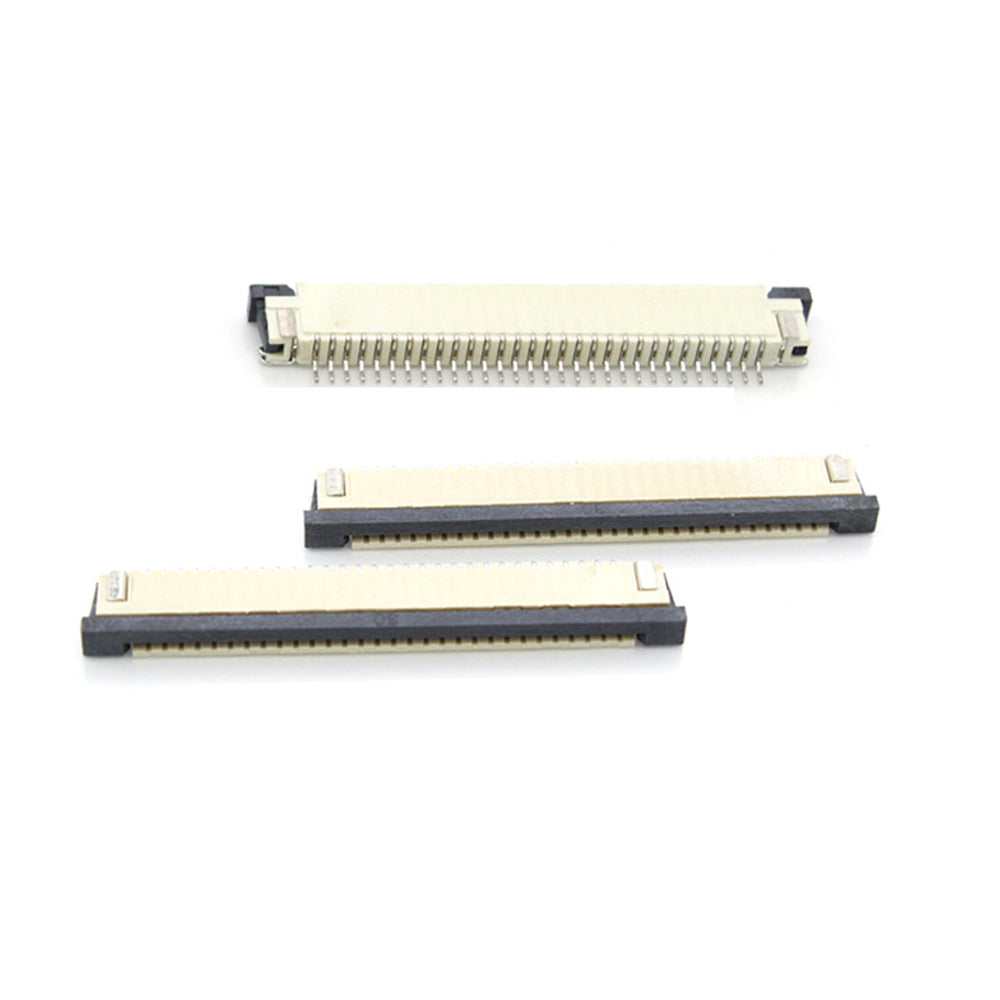

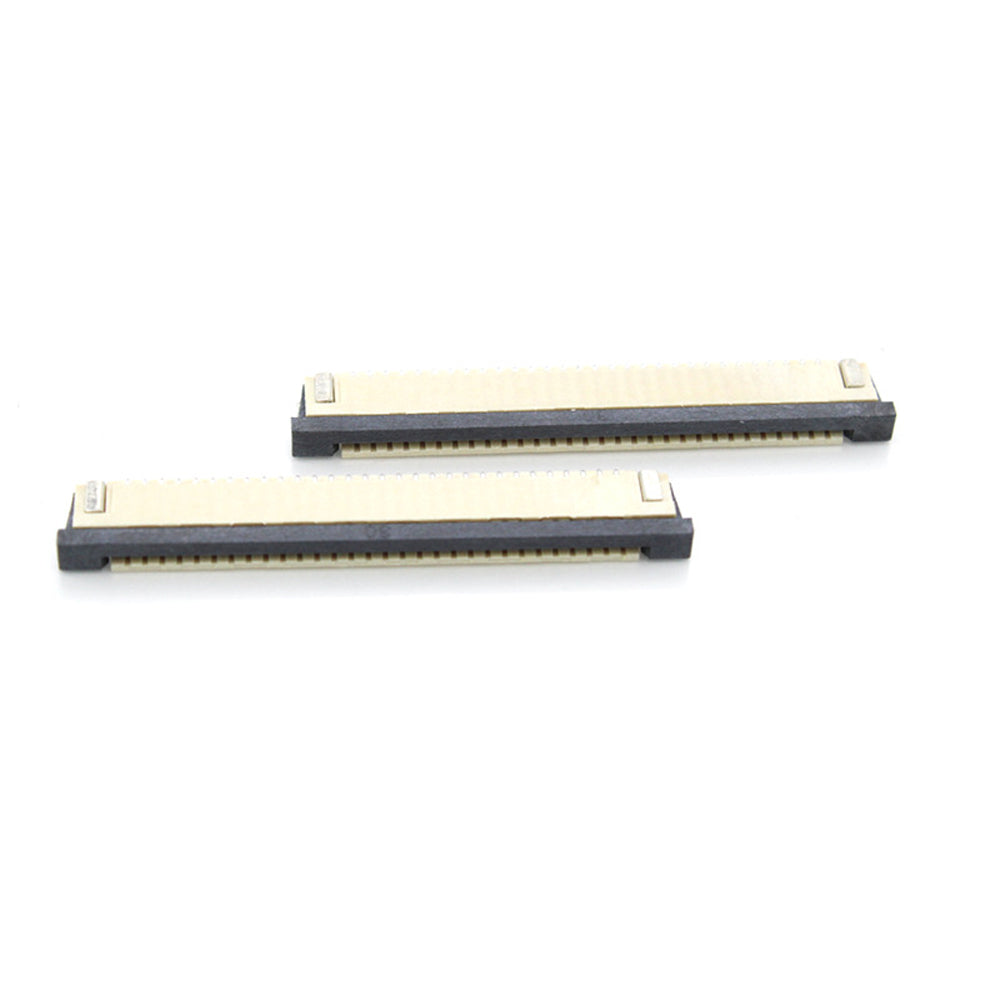

Кабельная сборка с разъемом FFC (FPC) с шагом контактов 1,0 мм, 4-50 контактов.

Разъем FPC предназначен для гибких печатных плат, обеспечивая высокую надежность и простоту установки. Этот компонент поддерживает высокочастотную работу, что делает его идеальным для сложных электронных приложений, требующих целостности сигнала.

|

Технические характеристики

|

|||

|

Название продукта

|

Разъем FPC

|

||

|

Электрические/механические характеристики

|

Номинальное напряжение

|

50 В переменного/постоянного тока

|

|

|

Контактное сопротивление

|

≤0,03 Ом

|

||

|

Сопротивление изоляции

|

≥500 МОм

|

||

|

Материал

|

LCP UL94V-0 / Латунь / Луженое покрытие / Фосфорная бронза

|

||

|

Подача

|

шаг 1,0 мм

|

||

|

Рабочая температура

|

-25ºC~+85ºC

|

||

|

OEM/ODM

|

Поддерживать

|

||

|

Приложение

|

Подключение печатных плат (PCB) и гибких печатных плат (FPC) для механических и электрических соединений.

|

||

Pairs well with

Reliable Materials & Long-Lasting Performance

Precision Manufacturing & Secure Connections

Compliance & Export-Oriented

OEM and ODM

Кабельная сборка с разъемом FFC (FPC) с шагом контактов 1,0 мм, 4-50 контактов.

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Product Category

Terminal wires are essential connecting components widely used in electronics, communications, automotive, and home appliance industries.

Customized Wire Harness

100% Raw Material Inspection → Precision Manufacturing → 3-Stage Quality Testing → Packaging & Delivery

Raw Material Inspection: Verify material specifications, insulation performance and environmental indicators.

Precision Manufacturing: Adopt automatic equipment to reduce manual errors and ensure consistent product dimensions.

3-Stage Quality Testing: Includes initial sample testing, in-process random inspection, and final finished product testing.

Packaging & Delivery: Anti-static packaging for electronic components; customized packaging solutions for bulk orders.

Our Advantages

🔍 Full Certifications

ISO/UL/ROHS/REACH compliant

🛠️ Customization Flexibility

Tailor length, terminal type, color & shielding

⚡ High Reliability

Anti-corrosion, vibration-resistant & stable signal transmission

⏱️ Fast Lead Time

Standard models in stock, custom orders in 7–10 days

FAQs

Please read our FAQs page to find out more.

Can you help to design?

Yes,we are an OEM/ODM company,we have been specializing in wire harness and cable since 2014.

Can you provide samples?

Yes,the sample is avaliable to provide for testing or checking quality before mass production.

If I don't have any drawings,can you still quote my products?

Yes,but we need you to provide information about the length and gauge of the wire,the part number of the connector,etc.

What are the common applications of terminal wires?

Terminal wires have extensive applications across multiple industries:

• Consumer electronics: Used in smartphones, laptops, TVs, and printers for internal component connections.

• Automotive industry: Applied in engine control units, lighting systems, and dashboard circuits.

• Industrial equipment: Utilized in PLCs, sensors, and motor control systems.

• Household appliances: Found in refrigerators, washing machines, and air conditioners.