As we all know, the terminal design is precise, and slight touch will lead to deformation, which will lead to difficulties in assembly and poor electrical performance in serious cases. Next, we will introduce how the connection wire processing factory protects the terminal connection wire!

When the terminals are supplied, most of the disk mounted circular terminals are shaft mounted. The chain terminals are protected by paper tape, and the outside is protected by paper customized plates or plastic shafts.

In the process of production and processing, the terminal machine has corresponding shafts to fix the terminal block! After wiring the terminal, put it into a fixed cup, protect it with a rubber band, and then put it into the customized box. During packaging, if the terminals are exposed, bubble bags will be added for protection.

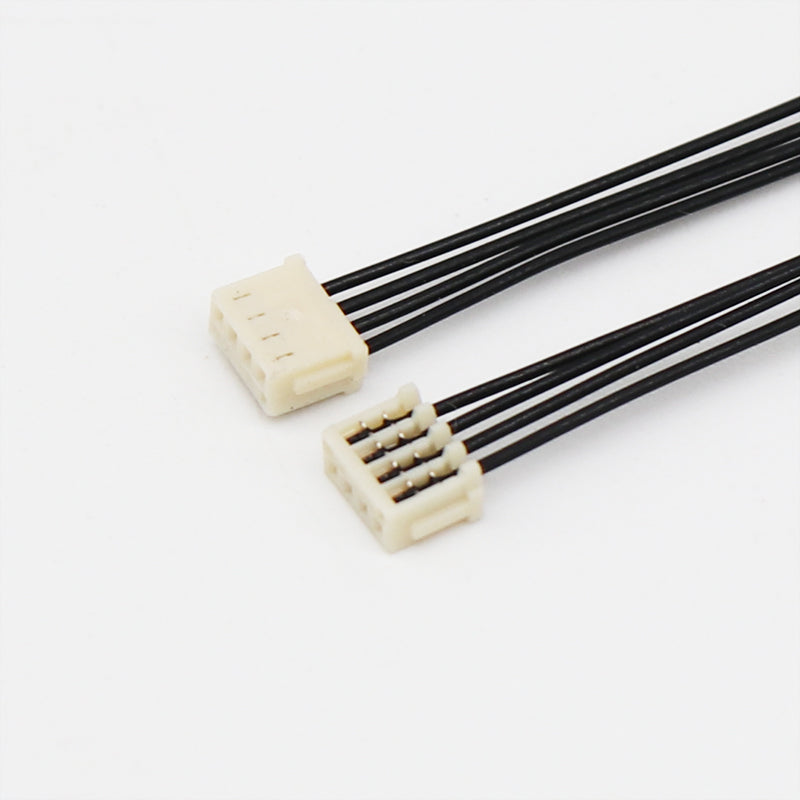

The harness is composed of connector and wire. Here is the structure and function of the terminals in the connector:

1. Contact end (contact part): the part that contacts with the pin of the needle base for power supply;

2. Wire barrel: part of crimping conductor;

3. Insulating cylinder: the part that fixes the insulating skin of the wire;

4. Bell shaped inlet sleeve: the part that protects the conductor from breakage and surface abrasion;

5. Spear hook: locking hook when inserting into the shell;

6. Cut off piece: residual part after cutting the strip;

7. Serrated bulge: groove in the wire barrel to ensure good contact of wires;

Share:

Product Characteristics of Terminal Wire

Function of Terminal Wire Harness Shielding Layer