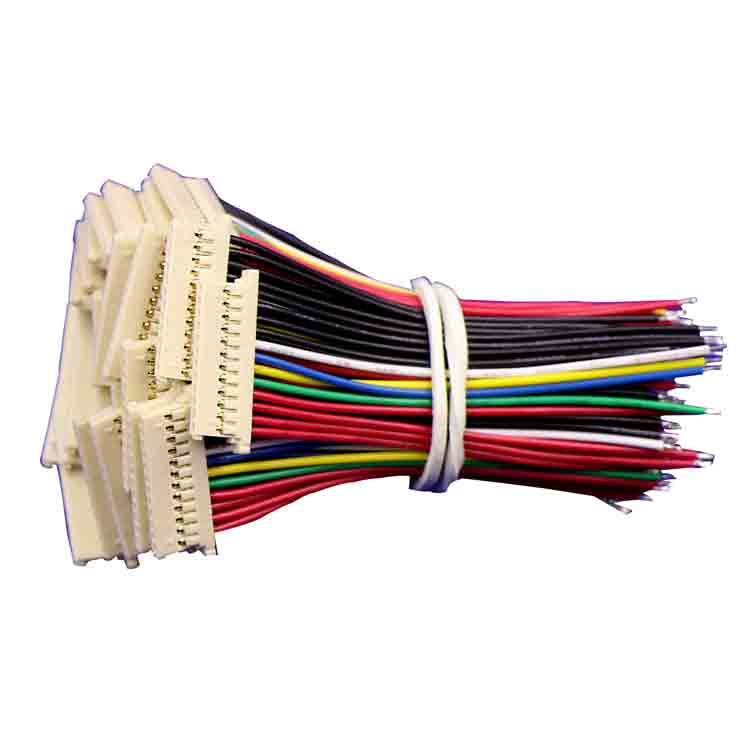

Four-step quality management system followed by terminal wire processing manufacturers

With the progress of the times, terminal wires are widely used in electronic products and digital products in people's real life. Therefore, the manufacturers of high-end terminal wires are very strict in quality control, because many of the terminal wires used in production are sophisticated product testing or connection. If the quality management system is not up to standard, it will be a bad news to test the product quality, Therefore, the quality management system of terminal wire manufacturers during production must be formal and complete, and the quality of products must be strictly controlled. The editor of Chinachem Electronics told you that the four steps of PDCA are mainly followed in the processing of terminal wire products. In fact, these four steps can be applied to many product quality management. Next, we will mainly explain what the four steps of P, D, C and A mean;

P, is the meaning of plan. It is planned that the relevant items of the product should be tested in the early stage of production.

D. It means "do". When you make a plan, you should implement it one by one.

C. Check, check and record the problems in the plan implementation and terminal line production one by one.

A. It is the English action countermeasure, which puts forward improvement countermeasures for the problems and suggestions for the prevention of recurrence in the later stage.

According to the above four steps of PDCA, the quality of the product is basically perfect in theory. Why do we say it in theory? Because there are always some uncontrollable factors in the specific operation, such as the inspection personnel is also very important, so the current terminal wire manufacturers also need to conduct knowledge training for the quality control personnel. At present, domestic manufacturers engaged in terminal wire processing are uneven. Experts in the harness industry said that new materials, new technologies and new processes will be continuously infiltrated into the field of terminal wire manufacturing, so it is very important to improve the manufacturing level of domestic terminal wire manufacturers.

Share:

Harness Manufacturer's Processing Quality Control

FPC Connector Wire Harness