Harness Manufacturer's Processing Quality Control

Harness processing products are characterized by a large proportion of manual processes, long product development cycle, complex loops, and many sub-parts. There are many changes in harness products from design to manufacturing, and human factors account for a large proportion. Therefore, harness quality control needs more powerful execution.

Quality is designed and manufactured, but inspection means are essential. Without the implementation of inspection means, the design documents will be empty and the manufacturing process will be disorganized. We know that the early import of quality objectives is through the main engine factory's input of contents such as drawings, technical agreements, quality agreements and other requirements at the early stage of the project. However, a good quality document is not established if it is not implemented.

Several key points must be grasped for the effective implementation of harness processing quality in actual production. First, leaders attach great importance to it and set a good example for the participation of all staff; The second is to strengthen staff training and improve staff quality. First of all, we can start with the ideological education of "quality first", form a strong quality awareness in the minds of the company's employees, and promote this awareness to be reflected in the work of every employee. This awareness is a willpower to consciously guarantee the quality of products, work and services of enterprises. 3、 Strengthen inspection and communication during implementation. It is mainly about the communication between the leaders of relevant departments, and then submitting the results to the management review, and timely modifying and improving the procedure documents to make the work documented and standardized; Then strengthen the internal audit and strictly follow the relevant regulations of the company. Another example is that the production department of the company takes the completion of the plan as an important work, so in the implementation process of this work, it is necessary to verify whether it is done according to the requirements through inspection. For example, the former engineering team leader failed to do the first article due to insufficient inspection execution, leading to batch accidents. If the team leader did the first article according to the system requirements for each order, and the supervisor always supervised, similar problems would be eliminated. Management is not one-way, not one-way, but two-way. Leaders require subordinates, and subordinates should have feedback to leaders. In this way, we can understand each other's work progress and solve problems in time. Inspection and communication enable our execution to be effectively controlled and promote our management level as a closed loop of management.

In short, in order to obtain good execution in the process of quality management and achieve the objectives of quality management, we must start from the management level, take the lead in active participation, adhere to the example, organize vigorously, implement the quality management plan aggressively, and continue to implement and improve it, so that the quality management can be truly implemented rather than a flash in the pan; Secondly, it is necessary to clarify responsibilities, rights and interests. The rights and interests of managers at different levels should be closely related to their responsibilities. In the process of quality management, each department and everyone should have a deep understanding of what I should do to meet the quality standards, strengthen process monitoring and management, ensure process control, and ensure the effective operation and continuous improvement of the quality management system.

Share:

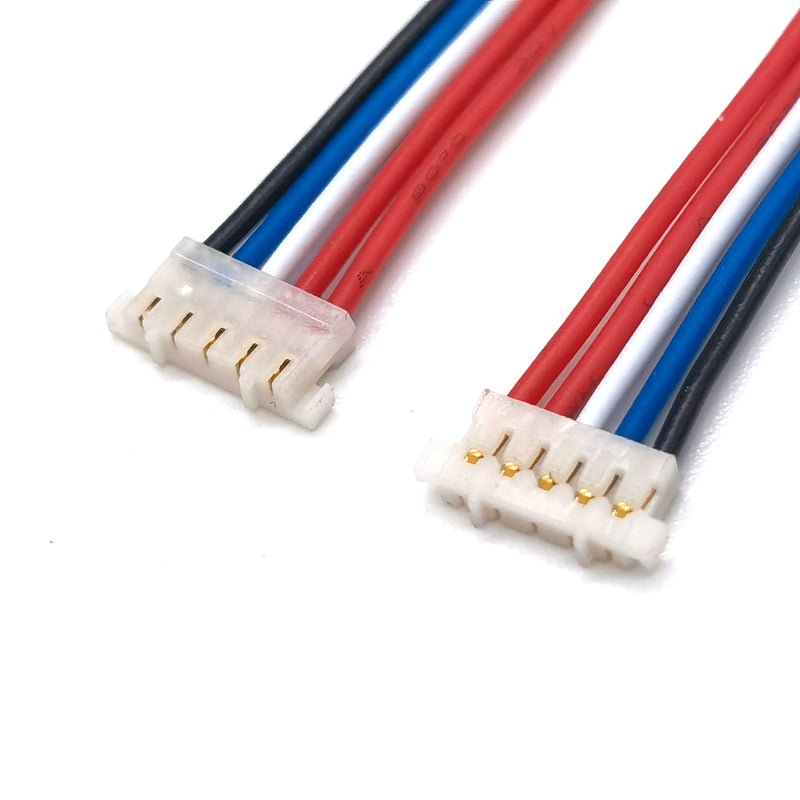

What problems are easy to occur at the terminal wire connector?

Four-step quality management system followed by terminal wire processing manufacturers