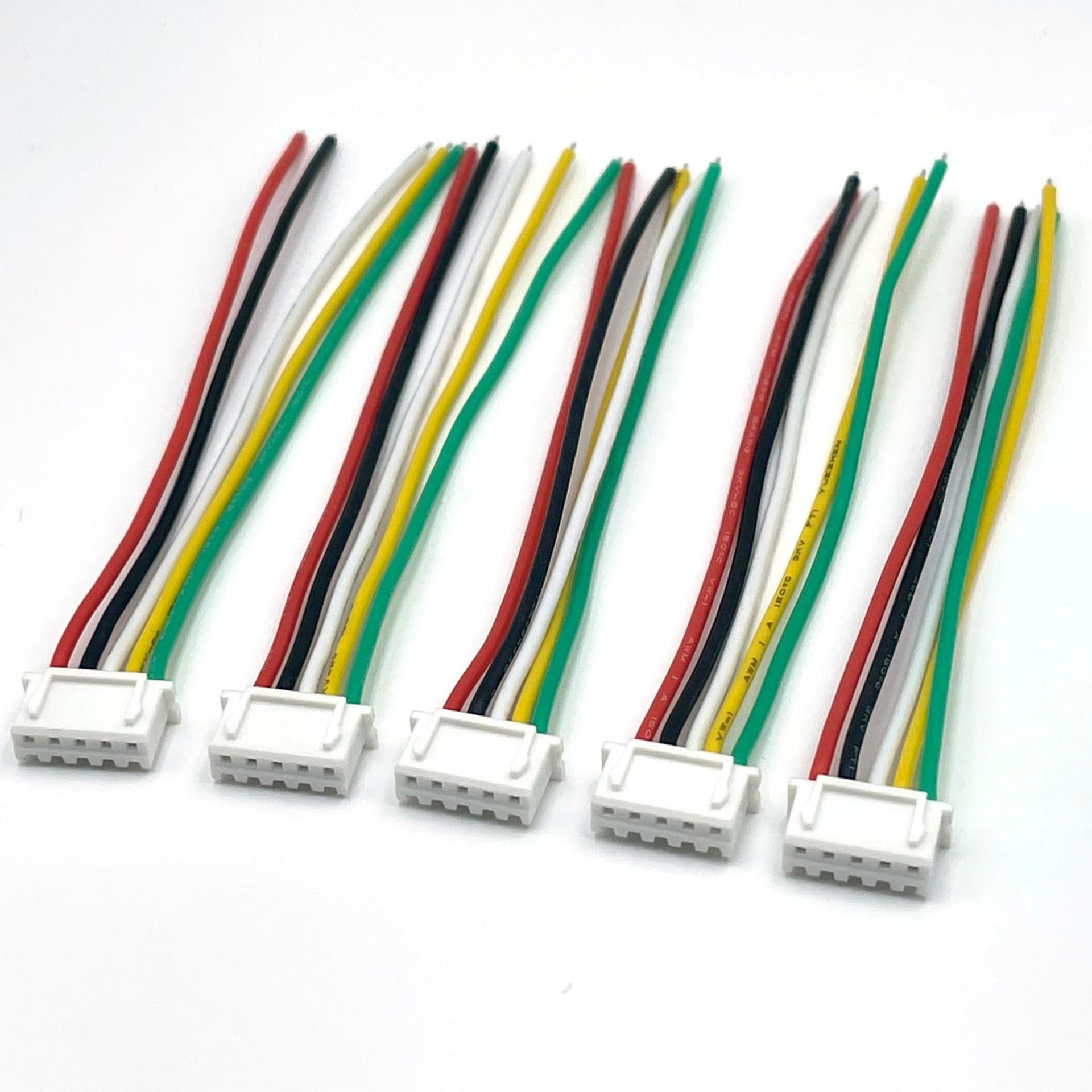

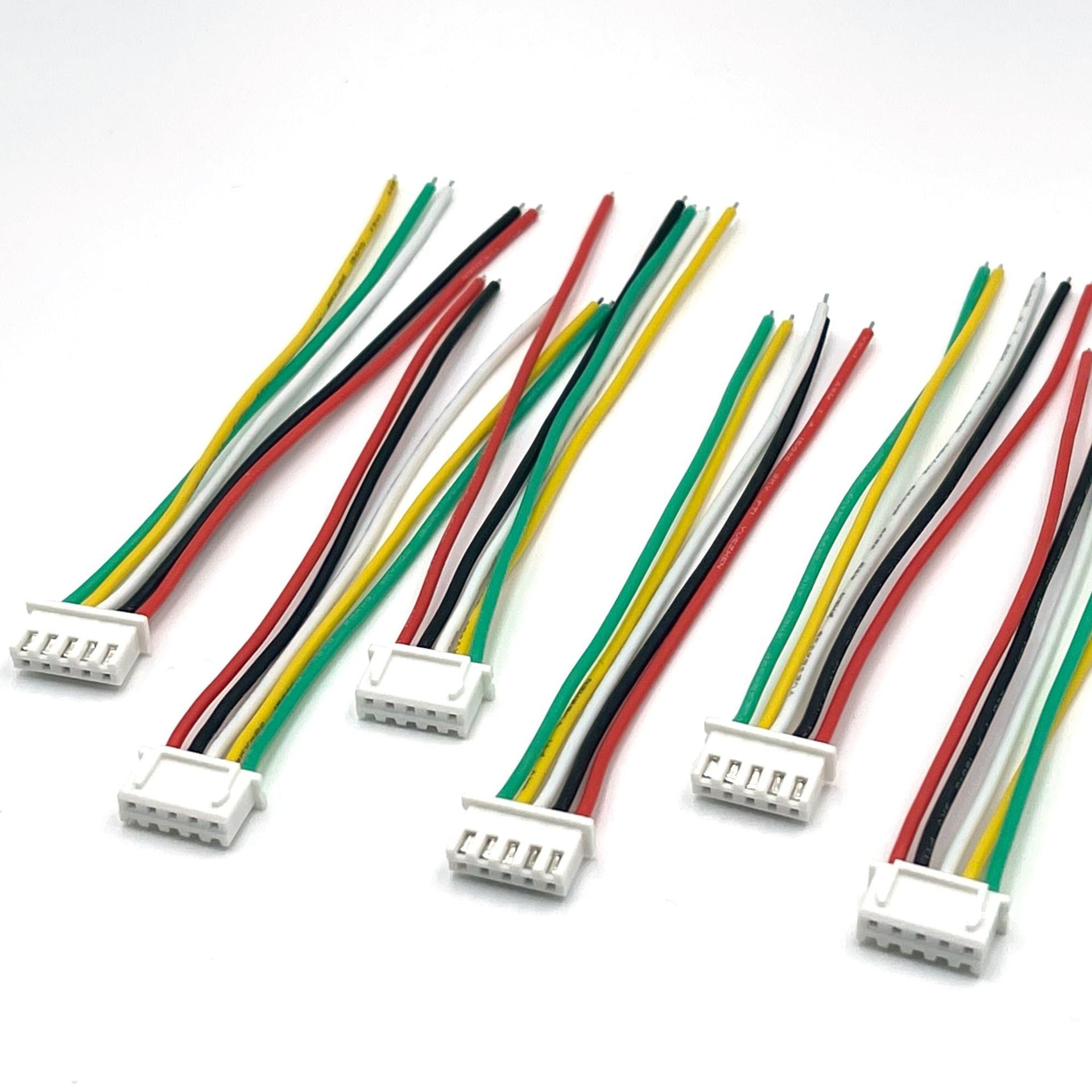

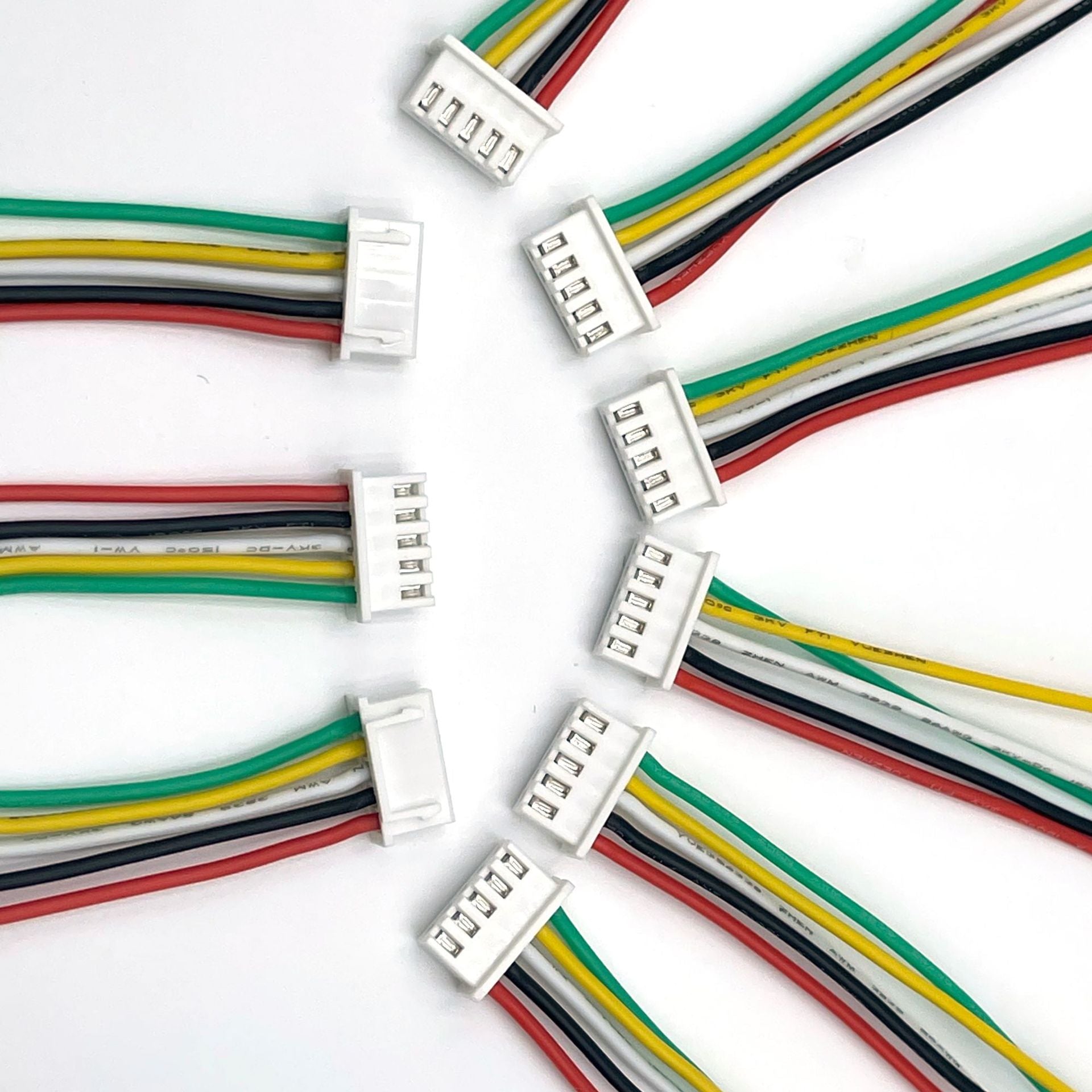

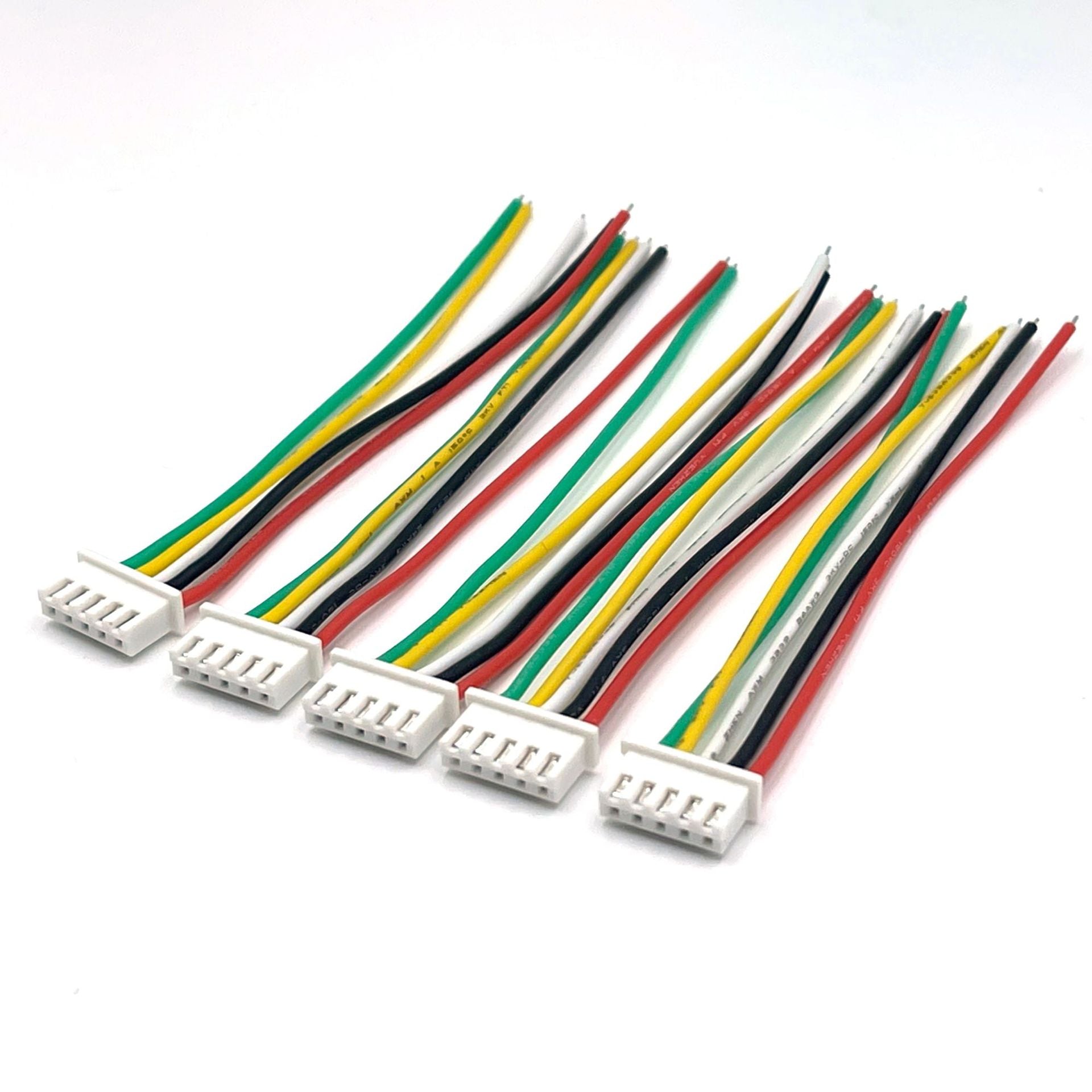

Manufactures of JST XHP-3 XHP-4 XHP-5 XHP-6 2.5MM Pitch Automotive Wire Harness Copper Cable

Professional manufacturer of custom JST XHP wire harnesses and cable assemblies. We engineer reliable, high-current solutions for industrial, automotive & energy applications. Get a custom quote.

We are a specialized manufacturer of custom-engineered wire harnesses and cable assemblies based on the JST XHP series. This high-performance connector system is designed for demanding, high-current applications. We take these robust components and build complete, ready-to-deploy interconnect solutions tailored to your exact specifications, ensuring superior performance, reliability, and safety in your products.

Our JST XHP Harness Manufacturing Capabilities

We go beyond simple distribution. We provide end-to-end services to deliver a finished product:

Full Harness Design & Engineering: Our team can design the harness from scratch based on your electrical and mechanical requirements.

Precision Crimping: We use automated crimping machines to ensure perfect, gas-tight connections for every XHP terminal, maximizing current flow and mechanical strength.

Custom Wire Configuration: We source and cut wires to your exact length, specifying the correct gauge (AWG) to handle the required current.

Complex Assembly: We expertly assemble the XHP housings, which feature a unique "Screw Lock" and "Lever Lock" mechanism for ultra-secure mating.

Quality Assurance: 100% electrical testing and mechanical inspection to guarantee every harness meets the highest standards.

Key Features of the JST XHP System in Our Harnesses:

High-Current Capacity: Rated for up to 12.0 A per circuit, supporting power-intensive applications.

Secure Locking Mechanism: Features both a Screw Lock for vibration resistance and a Lever Assist for easy mating/unmating under high circuit density, preventing accidental disconnection.

Wide Pitch Range: Available in 5.00mm, 6.00mm, and 8.00mm pitches, allowing for safe clearance at high voltages and easy handling.

Robust Construction: The housings and terminals are designed for industrial environments, with high-temperature resistance and durability.

Touch-Proof Design: Enhances operator safety by preventing accidental contact with live circuits.

Applications for Our Custom XHP Harnesses:

Our harnesses are critical in applications demanding high power and absolute reliability:

Industrial Automation & Robotics: (Motor drives, PLC systems, CNC machinery)

Energy Storage Systems (ESS) & UPS: (Battery packs, power conversion systems)

Telecommunications & Server Equipment: (Power distribution in data centers)

Renewable Energy: (Solar inverters, wind power control systems)

Heavy-Duty Vehicles & Machinery: (Electric vehicle powertrains, construction equipment)

Our Customization Options:

Circuit Count: From 2 to 24 positions, as per the XHP series availability.

Wire Specifications: Exact length, AWG gauge, stranding, and jacket color/material (e.g., PVC, SILFLEX).

Connector Options: Provide both plug and receptacle housings, or mate with PCB headers.

Additional Features: Include shielding, over-molding, strain relief, or integrate with other connector types in a complex harness.

Why Choose Us as Your JST XHP Manufacturer?

Deep Technical Expertise: In-depth knowledge of the XHP system and its application challenges.

Full In-House Capability: From prototyping to high-volume production.

Commitment to Quality: We use genuine JST components and adhere to strict ISO quality standards.

Cost-Effective Solutions: We optimize designs for manufacturability, saving you time and total cost.

Contact Us for a Custom Quote:

Ready to power your project? Send us your requirements for a rapid prototype and competitive quotation.

Pairs well with

In stock! Ships within 1-2 business days.

90-day risk-free trial

2-Year Warranty

Complimentary shipping & returns

Manufactures of JST XHP-3 XHP-4 XHP-5 XHP-6 2.5MM Pitch Automotive Wire Harness Copper Cable

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Product Category

Terminal wires are essential connecting components widely used in electronics, communications, automotive, and home appliance industries.

Customized Wire Harness

100% Raw Material Inspection → Precision Manufacturing → 3-Stage Quality Testing → Packaging & Delivery

Raw Material Inspection: Verify material specifications, insulation performance and environmental indicators.

Precision Manufacturing: Adopt automatic equipment to reduce manual errors and ensure consistent product dimensions.

3-Stage Quality Testing: Includes initial sample testing, in-process random inspection, and final finished product testing.

Packaging & Delivery: Anti-static packaging for electronic components; customized packaging solutions for bulk orders.

Our Advantages

🔍 Full Certifications

ISO/UL/ROHS/REACH compliant

🛠️ Customization Flexibility

Tailor length, terminal type, color & shielding

⚡ High Reliability

Anti-corrosion, vibration-resistant & stable signal transmission

⏱️ Fast Lead Time

Standard models in stock, custom orders in 7–10 days

FAQs

Please read our FAQs page to find out more.

Can you help to design?

Yes,we are an OEM/ODM company,we have been specializing in wire harness and cable since 2014.

Can you provide samples?

Yes,the sample is avaliable to provide for testing or checking quality before mass production.

If I don't have any drawings,can you still quote my products?

Yes,but we need you to provide information about the length and gauge of the wire,the part number of the connector,etc.

What are the common applications of terminal wires?

Terminal wires have extensive applications across multiple industries:

• Consumer electronics: Used in smartphones, laptops, TVs, and printers for internal component connections.

• Automotive industry: Applied in engine control units, lighting systems, and dashboard circuits.

• Industrial equipment: Utilized in PLCs, sensors, and motor control systems.

• Household appliances: Found in refrigerators, washing machines, and air conditioners.